How Fairway Golf Balls are Made

“Precision, Innovation, and a Whole Lot of Heart."

Our team in the United States and Asia have been working together to design the highest quality golf balls that will give your wallet a break. The manufacturing process utilizes sophisticated custom cutting edge equipment allowing us to manufacture golf balls at scale without compromising on ball quality and consistency. After being manufactured, our balls are hand checked by our associates to make sure they meet our high standards.

With our unique manufacturing partnership, Fairway was able to enter the golf ball market with a bang by offering premium golf balls that are 30% less expensive than the large brands.

With Fairway, you can feel the difference, both on the course and in your wallet.

Discover the science behind Fairway Golf Balls—from multi-layer construction to rigorous performance testing. We pull back the curtain so you can see exactly how we deliver pro-level quality, every single time.

Step 1: Rubber Mixing

Fairway uses a premium quality rubber in its ball cores. The firmness and make of the rubber varies across our different ball models which provides unique ball characteristics for players.

Step 2: Rubber Cutting

The rubber then gets rolled up and cut into pellets which help us form our cores. The cores are starting to take shape.

Step 3: Core Molding

Our pellets then get sent to a high compression molding machine. The pellets are compressed, shaped and baked in order to create a solid core for our balls.

Step 4: Core Polishing

The core then gets polished up in order to cover it up with the mantle, and then with the cover of the ball.

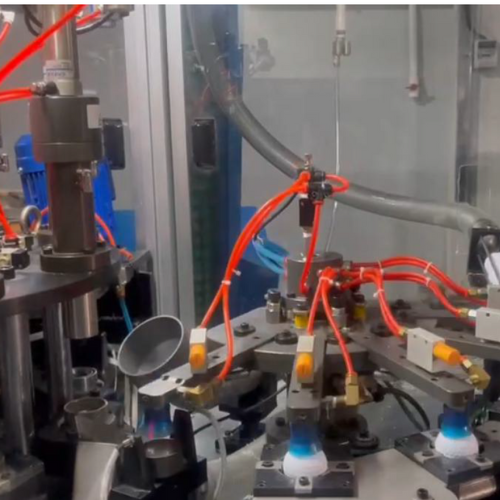

Step 5: Injection Molding

For our three piece golf balls, once the mantle of the ball is done through an injection process, it then also gets polished before the (Surlyn or Urethane) cover is added as the last layer of the ball.

Step 6: Cover Polishing

The ball cover then gets a final polishing to ensure a clean and regular dimple pattern for the golf ball.

Step 7: Logo Printing

Our balls then get their branding. This is when the Fairway logo is added to the ball. Don't forget, this is also the step where our extra long alignment aids are printed on the balls!

Step 8: Weight and Quality Check

Each ball is visually inspected and then weighted manually. All of our balls are also tested for near-perfect weight distribution using the liquids testing technique.

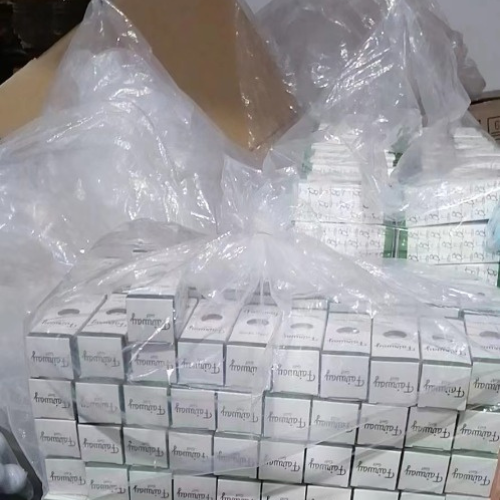

Step 9: Packaging

Our balls are then packaged in our unique Fairway boxes and pouches.